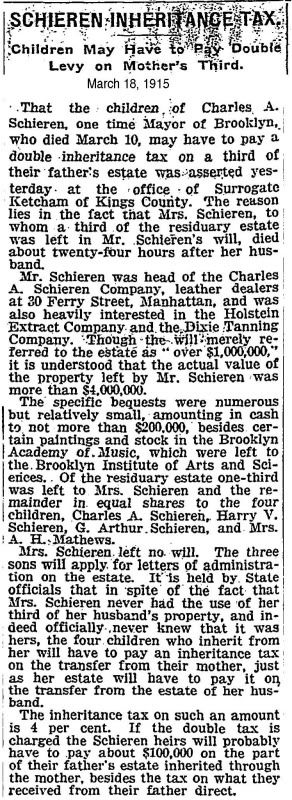

Charles A. Schieren & Co. Building

65-71 Cliff Street

New York City NY United States

THE MANUFACTURE OF BELTING AT THE SCHIEREN FACTORY

Although leather belting is one of the most common factory supplies it is probable that few even of those who operate belt driven machinery every day of their lives are familiar with the different steps of manufacture required to convert the hide into the finished product.

At the plant of Charles A Schieren & Co New York there is an especially favor towns the inhabitants depended to a large extent upon products manufactured within the town limits there were tanneries in the swamp district and although these have long since ceased to exist the leather business is still centered in this section and many of the wholesale leather houses and plants for the manufacture of leather goods are located there.

For the manufacture of high grade leather belting only the butt portions of the hide are suitable and this is the only part used for belts by this company.

The flanks shoulders and necks are sold for shoe leather. The butts are received in the basement where the hides are cleaned and softened by washing in a large rotating tank containing water. They are then submitted to a scouring process during which they are laid one at a time flesh side up on a table where blunt reciprocating scrapers pass over the hide and squeeze out the water and dirt. The hide is then laid over a beam the flesh con side scraped by hand and the pieces of soft leather not suitable for belting are removed These pieces are not wasted however for they are sold and used for making a compressed leather that is employed for a variety of purposes among them the heels of shoes The final step in the preparation of the hide are its treatment with oil on the grain side and tallow on the flesh side to preserve the leather and make it pliable and at last stretching and drying The butts are carried from the basement to the sixth floor where the manufacturing begins They are first put through cutting and scarfing machines a view of which appears in Fig 1 The cutting machines have a rotary knife like a circular saw without teeth but the knife and its spindle are above the cutting table instead of below It The leather is run under the knife the width of the strips being gaged by guides and the strips then go to the scarfing lucting covering Power is furnished by an independent steam and electric plant and the elevator service facilities for shipping the lighting etc are in accord with the most modern ideas for city buildings The location of the building on Ferry street is in the section known as the swamp directly east of Post Office Square In the early days of New York when as in other small machines where the ends are shaved off on a bevel about three inches long for the joints Before gluing the joints however the scarfed ends are finished to a fine edge by hand shaving squared with the sides and matched for length The scarfs are also scraped to remove any irregularities produced by the cutters of the scarfing machines The belts are built up and cemented on tables made especially for this work.

Friday, July 1, 2011

The Charles A. Schieren Company: Cliff and Ferry Streets, Part 1

We viewed this building, located on 30 Ferry Street, near Cliff, in the previous post. 100 years ago this area, part of Ward 2, housed many manufacturing businesses. This particular one, evidently made Mr. Schieren quite wealthy

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment